Sex: M

Sex: F

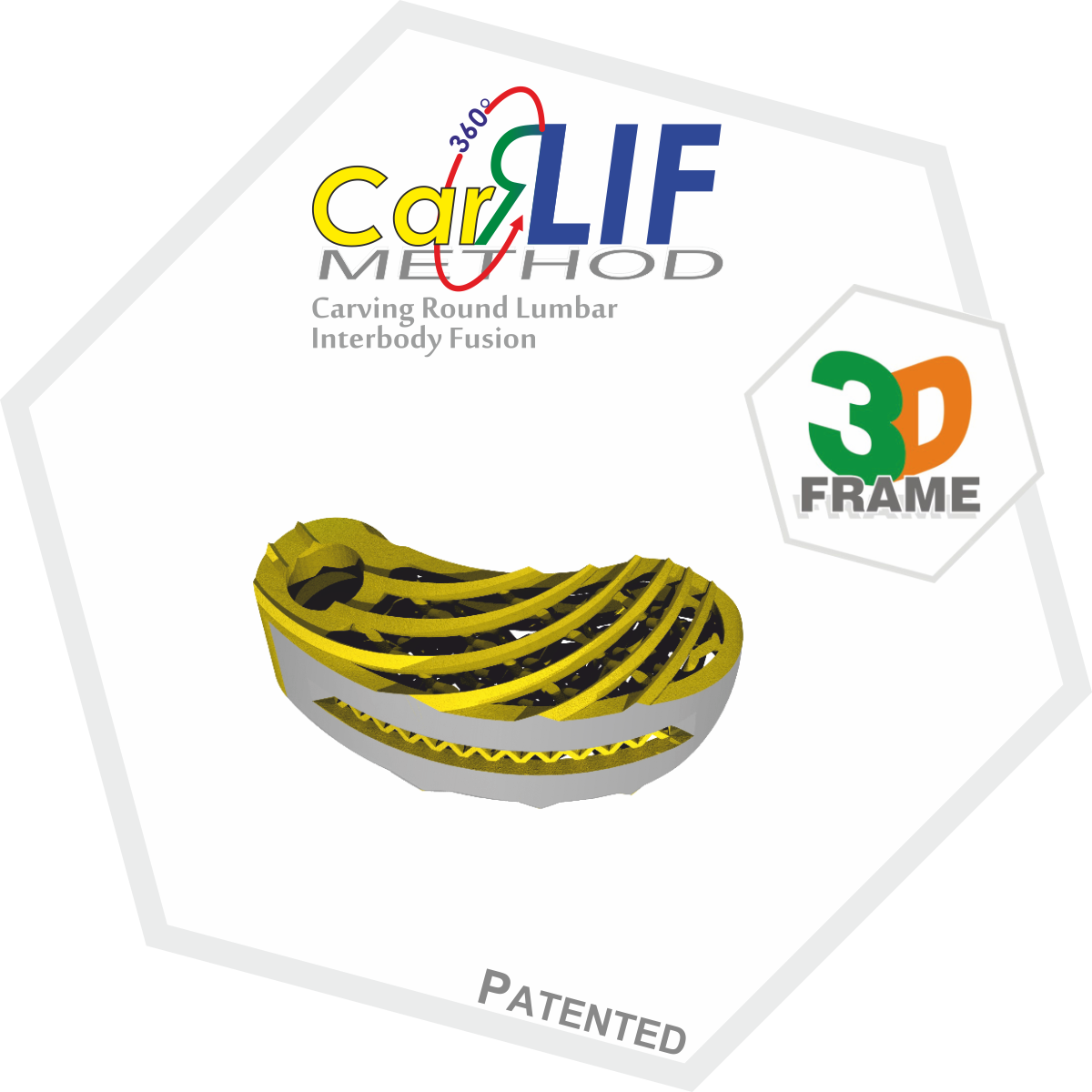

The first LfC’s 3D-Frame-Ti implant was the CarЯLIF (Carving Round Lumbar Interbody Fusion) – it is the first 3D printed, curved spinal cage worldwide. The clinical implantation started in the year 2011.

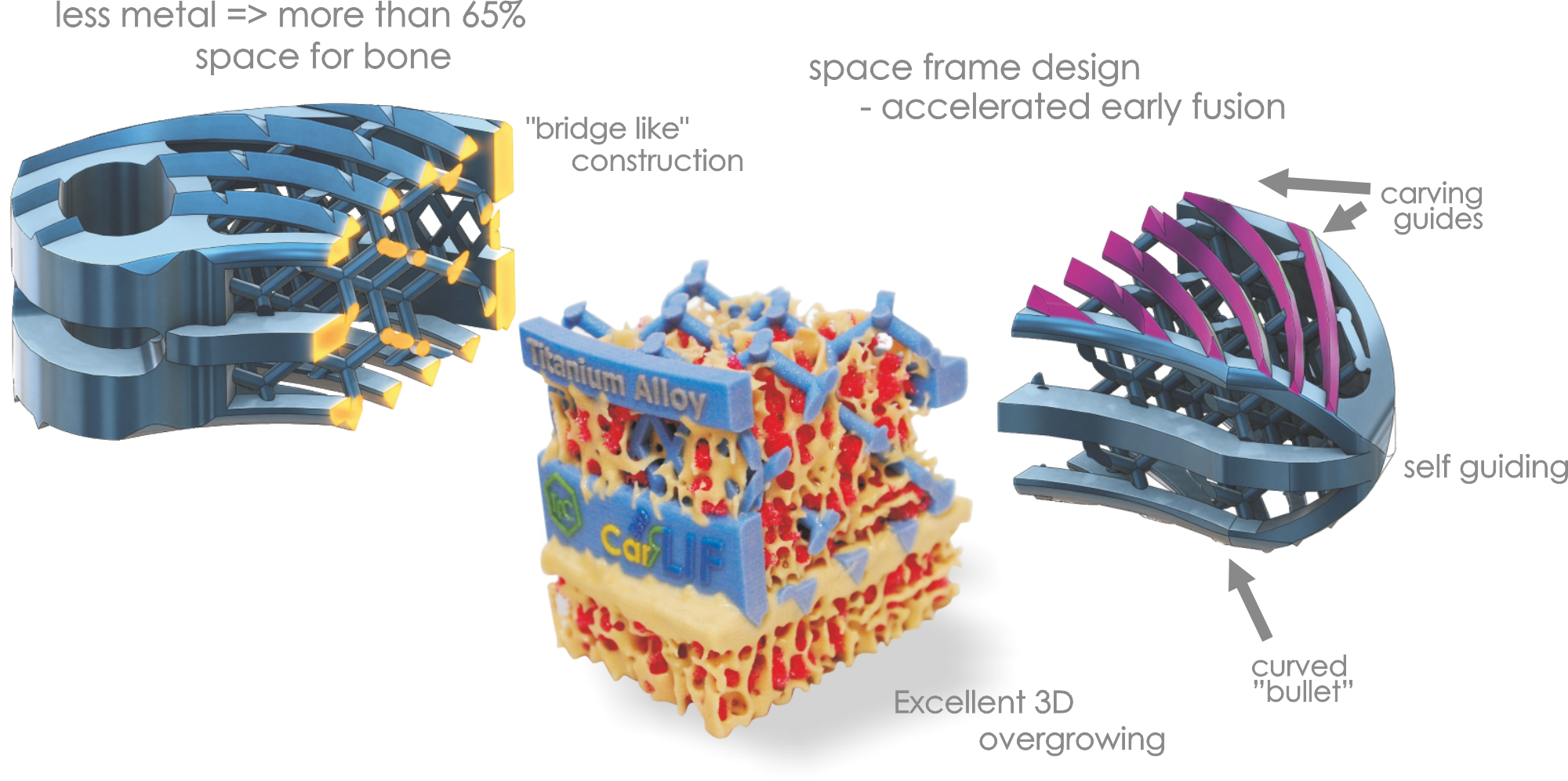

This cage combines the fusion enhancing features of the 3D-Truss-Ti structure together with the precision of insertion and placement provided by the unique “carving guides”. It is still the “flagship” implant of the whole CarЯLIF-family – a group of implants based on 3D-Truss-Ti Electron Beam Technology – which has been applied for the first time in spinal implant by LfC.

Those implants constitute a new significant step in spine surgery due to their special function enhancing new trend in surgical treatment of the spine:

“Bridging of spine” with 3D-Truss-Ti construction

Publications:

Ciupik L.F., Kierzkowska A., Sterna J., Pieniążek J., Cieślik-Górna M. „Bridging of spine” – titanium alloy and polymer PEEK for intervertebral stabilization of spine. Engineering of Biomaterials; 2015; 133: 14-21.

The others about us:

https://www.youtube.com/CarRLIF

http://www.biomat.krakow.pl/CarRLIF

https://link.springer.com/CarRLIF

FUNCTIONS

FEATURES & BENEFITS

Sex: M

Sex: F

At the end of the 20th century, technologies stemming from aero-space engineering opened a world of new possibilities in 3D spatial architecture. LfC managed to transmit this space technology to the field of spinal implants. Electron beam melting (EBT-Electron Beam Technology) of Ti-alloy powder with temperatures over 2000 deg. C in a vacuum chamber -that is the essence of technology used to create a new generation of 3D-implants. Apart from the structure itself, which favors bone ingrowth within the spatial cells, the implant’s design enables an accelerated osteointegration mechanism reducing fusion time by 40-50 percent and more. This new phenomenon was studied and called „Ivy-like mechanism, L.C.” as a metaphor for the natural growth process of ivy, which climbs along the specially made rough surface of truss design.

Publications:

Ciupik L.F., Kierzkowska A., Cęcek J., Pieniążek J. Sterna J., Cieślik-Górna M. The use of incremental technology to produce 3D-Truss Ti6Al4V implants which improves the spinal treatment effectiveness. Key Engineering Materials; 2016; 687: 179-184.

Bulletins:

BULLETIN No. 03/2020

BULLETIN No. 02/2020

Ciupik L.F., Kierzkowska A. Technology-biomechanical evaluation of metal biomaterials derived by layer technology. Engineering of Biomaterials; 2010; 93: 14-18.

Poster: Innovative 3D-Ti-Printing in a Worldwide spinal surgery